The Golden Gate Lotus Club remembers our local premiere parts supplier, Dave Bean.

In memory of Roger Becker

Zenos Factory Tour

During our our trip to the UK as part of the 2016 GGLC UK Lotus Trip, we were able to get a tour of the Zenos factory in Wymondham. If you havent heard of it before, Zenos Cars was founded in 2012 by Ansar Ali and MarkEdwards who had both spent time at Lotus and Caterham. I was lucky enough to attend the US unveiling of the Zenos E10S and was very impressed with what I saw. It struck me as an equivalent of the Lotus 211 and had significantly better fit and finish than the average Caterham I have seen in the US. Zenos hates the term “kit car” and stresses that they build the whole car but the reality is that to sell in the US they have to follow the Caterham model and sell them as kits which essentially work with only one specific engine. There are a bunch of reviews on the web for folks who want more details of the cars themselv es but I wanted to talk about the factory tour itself.

We were lucky to have their Operations Director Matt Windel give us the tour and they were extremely open to having the 15 of use traipsing through the shop. There were a couple of things they asked us not to photographs but other than that we had full access.

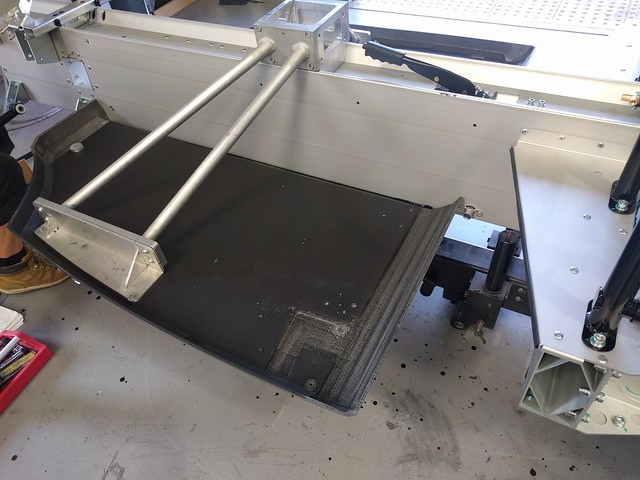

We start off at Station 1 where they essentially build the base chassis by mating the various subframes. As you can see below, the chassis has an extruded central spine that has a rear subframe bolted and bonded to it. The spine leads to great rigidity in the chassis and is also used to carry both wiring and coolant similar to the side sills of the Elise.

This is also the step where a jig is used to attach the carbon fiber floor pan which is the first part of the carbon “tub”. They use an innovative process to create panels from recycled carbon fiber and drinking straws to form a honeycomb like structure which had 90% the strength of virgin CF at around 10% the cost. This is what allows them to sell essentially a carbon tubbed car for ~$50,000.

At Station 2 the cars receive the rest of their carbon tub along with the front suspension. The tub integrates side impact tubing which is hidden inside the body and leads to the clean looks of the car. I also like the very Lotus-like design where a single front bracket holds the radiator, lights and front bodywork. They have tried to minimize the part count in general which results in the same part often performing multiple functions. I also like that the front suspension is designed to be sacrificial and a simple shunt will not write-off the entire chassis.

Station 3 is all about engine installation. The Zenos uses variants of the Ford Ecoboost engines that range from 200 bhp all the way to 350bhp in the range topper. This guarantees that the engine parts will be very easy to find worldwide though they do use their own locked ECU which is less than ideal for the US market since it will make it harder to use the full range of Ecoboost aftermarket products.

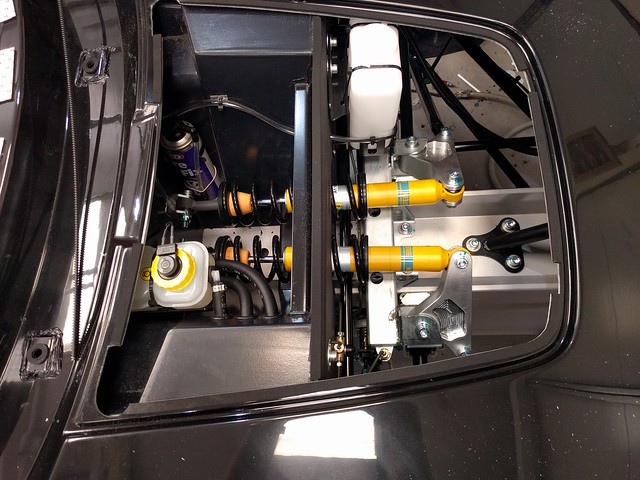

At Station 4 it really starts looking like a real car with the rest of the body going in as well as the installation of the adjustable inboard front shocks.

The car then goes through the alignment process and a final quality test before being readied for deliver. This beautiful custom painted E10R is the 100th Zenos produced and was to be delivered to the lucky owner the next day.

My thanks to the Zenos crew for talking the time to walk us through the factory floor and answer all our questions. The Zenos is a very impressive car and the closest you will come to a street legal 211 in the US. If this has piqued your interest you should head over to the Zenos Cars North America website and see what cars they have available.

Lotus Elise Suspension comparo: Base Vs Nitron 46mm SA Vs Penske SA

One of the great things about being a car guy in CA is that there is a large number of fellow addicts around. This means that if you ever want to put some high dollar upgrades on a car you can usually find someone with a similar setup and get some first hand info about it. The latest to take advantage of this was Vincent from the GGLC who has been thinking of getting a set of single adjustable coilovers for his Elise and was having a tough time deciding between the Nitron 46mm Race Pro 1-Way and the BWR Penske Single Adjustable. Since the shocks run $2500+ he sent out some feelers on the forums and was able to get 3 cars together to try some back to back to back driving on some interesting roads for a highly subjective and completely unscientific comparison.

Mag Blue (Vincent)

2005 Elise

Base suspension

LSS wheels

R888 tires

Black (Scott)

2008 Exige S 240

Nitron 46mm Race Pro 1-Way (450/600 “soft” springs)

Exige Wheels

R888 tires

A-arms for extra camber

Titanium (Rahul)

2006 Elise

BWR Penske SA (500/700 “street/track” springs)

Rota wheels (15/16)

RA1 tires wider than stock (205/50R15 245/45R16)

Aligned, lowered and corner balanced to BWR spec

Route

The road we used for the test was CA-35 from CA-92 upto Alices Restaurant which is an extremely bumpy road with lots of cracks and undulations. It is however quite a twisty road so is very popular with sports cars, bikers and cyclists. We also did drive La Honda road from Alices down to CA-1 but that section of road is so smooth that we could barely tell the difference and ended up using the original stretch again.

This was far from a scientific test and is basically about subjective feel of the various suspensions on a fairly bumpy road. We did not have any specific test criteria going into this and just wanted to drive all 3 cars. I am just going to describe my feedback from all 3 in the order I drove them:

Nitron 46mm Race Pro 1-Way (450/600)

The first car I drove was Scotts Exige S240 on the Nitrons. The car was set to 15 FFH front and rear which is a little softer than the recommended Nitron settings. The two things I noticed were that the steering was a lot lighter (extra camber A-arms) and that ride did feel pretty harsh on the on the bumpy sections. I had plenty of confidence in the car but I was feeling a lot of bumps and vibration through both the seat and the wheel. That said it certainly was not undrivable – just harsher than I would want on an everyday drive.

Lotus Base Suspension

I thought the Nitrons were harsh but when I drove the base car over the same section of road I realised just how much worse the base car is. It was crashing and skipping over the bumps and got lots of unpleasant feedback through the wheel. I should add that this is in relation to the Nitron/Penskes only – the base suspension Elise is still an incredibly capable car and I drove mine for 90k miles on that suspension including dozens of trips down CA-35. Driving the base car is still a great experience and only felt bad because it was sandwiched between two more capable (and more expensive) setups.

BWR Penske Single Adjustable

After driving the other cars I took my car for a spin down the same road just to see how it handled those bumps. While I have ~800 miles on these shocks most of them were at COTA and I had not driven a truly bumpy road on them before. The car started the day in my “highway” settings of FS/FS-5 which are significantly softer than BWR suggested settings for the street. These settings disconnect you from road harshness and expansion joints but can hit the stops on big bumps which is no fun. After Vincent drive in my car he said it felt too soft so I moved it up to FS+10/FS+25 for Scott before following him on the second run. I did notice that the rear appeared to be “bouncing” a lot over the bumps which is something he reported as well at the next stop. I started out the first couple of miles on the same settings and quickly realised that while there was no high frequency harshness the car was just too bouncy and underdamped over the bumps. I pulled over and bumped it to FS+15/FS+35 which gave it a much more compliant ride with minimal harshness (less than the Nitrons).

Final results

In the end I have to say that the Nitrons and the Penskes are both a significant improvement over stock in terms of comfort and drivability. From this informal test I’d have to say that the Penskes can be adjusted to a softer setup (this might also be due to the extra tirewall from the 15/16 wheels) but some folks can find that to be too “Cadillac-y” and unconnected. The Nitrons were very good on the smoother sections but cannot be made as “soft” as the Penskes. That said we dont know if the softer adjustments cause the Penskes to lose a bit on track (not AutoX). I have driven 3 days at COTA with Penskes but that is possibly the smoothest track in the US plus without a back-to-back its hard to really judge.

In the end if you want a good aftermarket suspension you cant really go wrong with either of these options and both vendors will work further with you to come up with the right package for your specific needs. They are both a massive upgrade over stock in terms of drivability and I wish I had bought them years ago instead of waiting 90k miles to make the change.

Update: Added a note that the ride comfort of the Penskes is affected by the extra tire wall from the smaller wheels.

Roberta Bean Finds Some Time to Volunteer

When Dave and I were starting Dave Bean Engineering back in the 70s and growing it in the 80s, our workweeks were seven days, 10-14 hours a day. (Yes, we both were younger back then, but still ….) Sourcing Lotus parts in the UK and elsewhere for our customers simply took a lot of time. Communication with suppliers was by phone (time differences), telex (remember those?), and trans-Atlantic trips. Invoicing and accounting were done by hand.

By the time we were fully relocated in Calaveras County, things had loosened up a bit. We were now computerized and communicated mostly by fax, although UK trips were still on the menu. In 1992, I was invited to join the Calaveras County club of Soroptimist International, a worldwide service organization for business and professional women. If you’re not familiar with Soroptimist, please visit www.soroptimist.org and www.sicalaverascounty.org. There is a link to our Facebook page on our website. We are a 501(c)3 organization.

Our service projects to support the Soroptimist mission to improve the lives of women and girls through programs leading to social and economic empowerment are funded by fund raising efforts throughout the year. One of our major fund raisers is Chairs for Charity—a collaboration with the Calaveras County Arts Council. It’s a fun event. Local artists decorate (or make) chairs, which are auctioned off (both live and silent). A couple of examples appear at the end of this article. One of the things we incorporated into our last event was a “big ticket”, non-chair live auction item. One of our club members donated two weeks at her vacation home in New Mexico, and it did go for a nice amount.

We’re now looking for a similar item for the event on January 31, 2015, but we’re thinking—with the price of gas these days—of perhaps something a little closer: Monterey, Carmel, maybe, or the beach above San Francisco (Bodega Bay, for instance) or perhaps Lake Tahoe.

I’m hoping one of the GGLC members might have a vacation home or timeshare they’d be willing to donate some time at. It needn’t be two weeks (in fact, two people split that up). Even a weekend would be wonderful.

If this is something you would be interested in, please let me know and thank you. Soroptimist International of Calaveras County will provide you a receipt for your donation. I can be reached at Dave Bean Engineering, (209 754-5802. at home, (209) 754-1256, or by email to roberta@goldrush.com.

2000 miles in a Seven

One of things that I’ve always wanted to do in the Seven was go on a long road trip. However I’ve always been afraid of mechanical breakdowns which is why I took the Elise to LOG 31 in Vegas two years ago. Once the 2013 West Coast Lotus meet was announced for Seattle in July, I started toying with the idea of taking the Seven but kept prepping both cars so that I could make a last minute decision. As luck would have it I was changing the oil on the Elise a couple of days before the trip and found a transmission leak which meant that the Seven was now the only option for the 2000 mile trip.

I started checking weather forecasts along the route and thankfully it appeared to be little chance of rain which is a good thing in a roof/door/window/windshield-less car with potentially dodgy electrics. I did see that a heat wave was expected with temperatures in excess of 100F but having done a 98F trip down to Buttonwillow in the past I felt pretty confident that I would be able to handle it with my cool suit. In terms of mechanical reliability I had driven the car several hundred street miles in the past few months which made me feel good about making it to Seattle without an issue. The risky bit would be the track day at Pacific Raceway but if a terminal issue cropped up Rob @ DiestchWerks said he would be able to trailer it back on his race trailer if needed. With all this worked out I decided to take the Seven on an epic roadtrip.

I started out with fellow Ultralite owner and GGLC member Jim R who was going to drive up with me till Shasta City. We started out at 7 am as I wanted to cover as much ground as possible before sunset and had set myself the goal of reaching Medford at the very least with Eugene as a stretch goal. Since the planed distance was only just over 400 miles, we even took a slightly longer route to get the obligatory pic with the Golden Gate Bridge just like my last trip tor WCLM 08.

The first couple of hours went quite well and we covered 100+ miles before it warmed up enough that I had to start up the cool shirt which is basically a shirt which pumps cold water through it to keep the wearer cool. They were originally designed for surgeons but are now used by firemen, military, hazmat and of course racing. I originally picked up a cool shirt to use it in Lemons racing but after I got the Seven I realised that it was the perfect way to stay cool in the car as well. Jim and I made it up to Shasta Lake before stopping for a bite to eat at the Basshole Bar & Grill in Lakeshore CA just after noon.

By this time the time the mercury was really rising and Jim decided to head home while I continued on to towards Oregon. As I entered the mountains below Mt Shasta the weather was quite pleasant (though assisted by the Cool Shirt :)) and I was feeling quite good about my progress for the day. That came to crashing halt as I got passed the mountains and entered Oregon where the weather really shot up. The temperatures in Ashland were well above 100F (Jim saw 108F at one point on his way back) and it was so hot that I literally just pulled off the highway and parked under a tree.

At this point the ice cooler part in the Cool Shirt came in handy as it meant that I had some cold refreshments to help cool myself down. I then decided to try driving a little bit without my helmet on but the hot air hitting me in the face made it hard to breathe so I put the helmet back on and kept going in short 30 min stretches. By around 5 pm the temps started dropping and by the time I got to Eugene at 6 it was pleasant enough that I took the helmet off off and cruised up to Salem, OR where I spent the night. The next day I was up and running again and made it to Seattle despite some extreme heat and traffic in the Olympia area. My dash got so hot at one point that my phone overheated and shut down. In the end I did make it to Seattle with the car running like a champ with only the organic bit behind the wheel having issues with the heat (see below). BTW if you think I’m complaining too much about the heat, it was so bad that the WDOT had to shut down a bridge and water its deck to prevent excessive heat expansion.

The first official event at the West Coast Lotus meet was a track day at Pacific Raceways which was put on by the folks at ProFormance Racing School. We started out with some lead-follow laps as most of us had never driven the track before. Pacific Raceway is a fairly technical track with 350 feet of elevation change which means you have a lot of blind late apex corners. Plus the track is very different from my usual tracks with very little run-off or exit kerbing and plenty of surrounding greenery – it feels more like a hillclimb course instead of a closed circuit track.

After a few sighter laps and some conversations with the instructors I was able to work out a reasonable line and really got into the groove at the track. As you can see from the video below I was not pushing very hard as I did not want to break anything at the track. One thing to note is that I did discover that top speed on my car is 125 mph which I hit 2/3rd of the way down the looong straight – it was actually a bit disappointing as I thought that the Seven was a bit faster than that but I guess crappy aero performance really does take its toll. We did have a modified Elise (slicks, 300 hp, sequential gearbox, paddleshift) that was quite a bit faster and was hitting 140 mph down the same straight.

The most interesting moment of the video above was when I go off at the 14:20 mark. This was due to a stuck throttle though luckily it was stuck partially open and not at full throttle. I didnt realise this initially as the revs do go down when I get off the gas but the car did not slow down enough. I keep adding more brake pressure and end up locking the front wheels before I go off the course. At this point I go both feet in and the engine revs rise to ~4k rpm and I realise what the problem was. I was able to use partial clutch to get into the pits and killed the engine as soon as I got in. When I opened the hood I found that the bracket that the external throttle release spring attached to had broken off and the stock throttle spring was not strong enough to close it all the way which is why the engine was stuck at part throttle. I was able to ziptie the spring back together to get the car going again but called it quits for the track day as I didnt want to risk it happening again on course.

After the track day I headed over to the event hotel which had organized some excellent “Lotus Parking” for the duration of the event. This meant that we not only got to see the cars all together, but we also got to chat with all the owners as we came in and out of the lot. After the cocktails and reception many of us headed out into the parking lot to check out the cars and shoot the breeze with other Lotus fans.

Day 2 started with an excellent tour of Paul Allens Flying Heritage Collection. Nothing to do with Lotus but it is an excellent collection of WW2 era machinery including airplanes, rockets and tanks. Many of the airplanes are still airworthy and are flown a few times a year. Its also right next to the Boeing Dreamliner factory where a bunch of planes were getting fitted for their customers. I highly recommend it for anyone who likes mechanical objects.

In the afternoon we headed over to the parking lot of Bellevue Community college for the WCLM autocross. It was a very tight course that you lapped multiple times to set a time. Most people were doing the course in first gear though due to my low gearing I was able to launch and do the entire run in second gear instead. The following video is of my 31.165 second run which ended up as the top time of the event. I was even able to avoid hitting “my cone” which folks were taking odds on whether I would hit it. Facebook users can see more photos from the autocross at the WCLM FB album

After the autocross we headed over to the Snoqualamie Casino where we had an excellent buffet dinner along with drinks on the roof right in the shadow of the mountains. Plus it was another great chance to check out the cars and we got a lot of regular casino guests coming by to ogle at the cars.

I was feeling a bit under the weather on day 3 so I skipped the SOVREN Historic Races and the parade laps at Pacific Raceway. I directly went over to the LeMay museum in the afternoon where we were taking a group photograph before dinner and a private tour of the museum itself. The album below shows some of the cars on display in the museum, as well as some shots of the cars lined up for the group photo. Another wonderful place to attend and much better organized than the original warehouses that they used when I first visited the LeMay in 2010. After the LeMay trip I was hanging out with some Canadian attendees at the hotel who were quite surprised to learn that I had driven the Seven all the way from CA. Hopefully at the next WCLM we can have a some of them drive all the from Canada instead 😉

The final stop on the WLCM calendar was at the Griots Garage retail store in Tacoma where we got look at some of their cars and also got a demonstration of their car car products. Not very Lotus specific, but they are definitely car guys as evidenced by their McLaren display below. I have to say that Doug and the ELCC really put on a great WCLM and are going to get a lot of repeat business the next time they host a WCLM.

After lunch I headed out around 2pm with the goal of making it back to Eugene, OR before nightfall. The return trip was going well until I stopped just before the WA-OR border and noticed that the left side of the car was covered with coolant. The upper radiator hose had sprung a leak and was dripping coolant under pressure.

I filled it up with some water and Rob @ DiestchWerks a call to see if I could get him to trailer the car back. It ended up he was about 45 minutes ahead of me so I limped the car over there while he stopped at an auto parts to see what he could find. In the end he cut the hose at the point that it was leaking at and used a plastic coupler and some hose clamps to put it back together again. I then got back on the road and started driving with frequent stops to check the coolant levels and to watch for any further leaks. I was able to make it to Canyonville before nightfall and stayed at the Seven Feather Casino which was the site of the WCLM 08.

I decided to drop my original plan to drive straight down I-5 as the temperatures in the central valley were expected to be well over 100F and I did not want to put additional stress on my cooling system. Instead I took US-199 over from Grants Pass to Eureka and then took 101 all the way to SF. This turned out to be a great decision because though the trip would be longer, it was much much cooler plus US-199 is an fun road to drive in a sports car.

After having lunch at the Samoa Cookhouse above, I took the famous Avenue of the Giants route through Humboldt Redwood Park which was another fun detour.

At this point I was far enough inland that it was starting to heat up again and I had to put my cool shirt on again. Plus the temps never went about 95 which meant that the cool suit was able to keep me quite comfortable. I then stopped off to meet a friend in Windsor, CA and was able to avoid much of the evening heat before making the final 90 minute drive back over the Golden Gate Bridge and through SF to get home again.

All in all the car ran quite well and apart from the throttle and coolant issues it gave me no trouble at all in over 2000 miles in some blistering heat. I got lots of weird looks and several photos taken of me on my trip but I have to say that it was great fun and I would say that all Seven owners should consider doing at least one long road trip in their cars – it is an experience that you will not forget and you’d be surprised how reliable our cars can be. Now where is WLCM 2014 going to be? 🙂

Rahul Nair

The Road to Elite Enlightenment

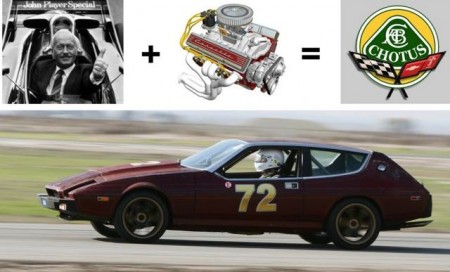

On December 4th 2011, a 1974 Lotus Elite with a Chevy V8 engine competed in a 15 hour endurance event at Buttonwillow, California.

It didn’t do very well.

This is the story of our path. You can follow it if you like. Probably best if you don’t though.

Step 1. Buy a Lotus Elite.

Possibly the hardest part of the operation, as there are likely less than 100 of these fantastic machines in working order in the US. We found our car by advertising a second hand fridge on Craigslist, then asking the guys who showed up they have a Lotus Elite they’d like to swap for the fridge. We asked him to throw in a couple of hundred bucks.

Step 2. Bring the Elite home.

We found out that Colin, being his usual efficient self, used the drive shafts as the upper suspension elements. With the diff in the standard place for the Elite (the trunk), towing quickly resulted in two flat tires as they impinged on the incredibly sharp shock tower brackets.

Step 3. Look for the rear brakes.

We found them in the trunk. With the diff. On the diff actually. And they’re drums.

Step 4. Remove the Interior.

Everyone knows that to be competitive in a race you should make your car as light as possible by removing the creature comforts such as passenger seats and the air conditioning. The Elite was originally a luxury 2+2 as it rolled off the production line all those years ago, but Colin was alive at the time, and simplify and add lightness was still the rule in Hethel. Removing all the interior saved us about 10 pounds, but vastly reduced the amount of tan corduroy we see on a daily basis.

Step 5. Build a cage.

In fact, we didn’t build a cage. It’s far too difficult for a Joe Shmoe like you and me. We took it to an expert cage builder who scratched his head at the challenge of finding enough metal in the car to weld to. In the end he built a complete under floor chassis to hold the seat to the cage. In the event of a really big hit the fiberglass body may part company with the cage, but at least we’ll still be in the cage.

Step 6. Install the diff.

We set aside about 3 days for this task, not really because the diff is hard to install, but that with the drums on the diff you have to connect brake lines to the diff when the diff is in place. We could have saved about 2.5 of those days if had cut large holes in the fiberglass by the transmission tunnel to access the brake lines from the back seat. We did this after spending the 3 days installing the diff.

Step 7. Get the Chevy V8 running.

This is ridiculously easy provided you don’t have the distributor set 180 degrees out. You’ll know if you’ve done this because 8 foot flames out of the carburetor are not normal. Neither is blowing the breather out of the valve cover into your overhead florescent lights.

Step 8. Go to the practice day on the Friday before the race.

A novice would think that the practice day is to tune up the performance of the car on track. It turns out that normal procedure is to hammer on the radiator fan shroud to try and reduce interference. Take the radiator out to have to hole you just made in it repaired. Bleed the brakes 9 times. Go out on track for ¼ of a lap and get towed in with an apparent fuel problem. Wonder what’s causing the blue smoke to come out of the exhaust but not have time to investigate it. Fail tech by putting the battery in the trunk, so that with a big rear end hit we have a heavy object to puncture the gas tank and a spark source to ignite it. Move the battery to the rear seat, and collapse in a heap from a 14 hour day working on the car.

Step 9. Line up for the start on Saturday.

Again a novice would think that this is to take part in the race. Instead this is so that we could get towed off after another ¼ of a lap with the fuel problem that we had the day before but didn’t solve. We installed an electric pump instead of the mechanical one and wondered why we still had a fuel problem. We replaced the inline fuel filter and wondered why we still had a fuel problem. We examined the interior of the carburetor and wondered why we still had a fuel problem. We found a kink in the fuel line right under the gas tank and knew why we had a fuel problem.

At last we got to run two laps of the track before getting black flagged for leaving blue smoke swath so bad we understood why James Bond liked Lotuses. Back to the pits we started taking the engine apart and wondered if we did anything bad to the internals when we spat flames out of the carburetor. Nah. That couldn’t be it.

Actually…

Backfires (frontfires?) could have blown the intake gasket, letting oil into some of the cylinders. Good job it’s easy to take the intake manifold off a V8 and replace it. While we’re in the pits we drained the ½ gallon of gasoline in the trunk and tried and figure out where it’s coming from. We connected tubes to the breathers that vented into the trunk. Finally! The car was fixed and we could get back out on track. Shame that racing for the day stopped 6 hours ago.

Step 10. Go racing!

Really! The car was ready and fun to drive! For two laps. Then we needed to change out the rear tires for smaller ones to stop them impinging on the subframe (see Step 2) we went back out but the car just got slower and slower…

The throttle cable was stretching due to a bad pull angle from the accelerator pedal. Another stop and an adjustment on the throttle made the car faster again, but it was a temporary fix as the cable started to fray in the sheath, making it stick.

In the end the Chotus completed 60 laps over 2 days but it did come back from Buttonwillow in better condition than how it went. We can’t wait for Infineon

By Steve Warwick

B-Team Racing

Photos by B-Team Racing and Vanhap Photography

Lotus Management on the Future of Lotus (GGLC Exclusive Interviews)

GGLC attended the North America launch of the new Lotus range at the LA Auto Show and got a chance to speak to senior management about their plans for Lotus and the challenges in launching 5 new cars in a short span of time. Short descriptions of the interviews and their major points are below but we recommend you watch the actual videos to get a sense about the future direction of Lotus

First up we spoke to Dany Bahar, the CEO of Group Lotus about his vision for the future of the company and why they were launching so many cars in such a short timeframe. Major points that he confirmed were:

- Not all cars will be going to aluminium skins, the Elise will remain a composite body

- Motorsports activities will include Evora GT4, Evora GT2, IndyCar (bespoke engine and aero)

- Simultaneous worldwide launch with an intended volume of 6-7000 cars per year

Next up was Donato Coco, Head of Lotus Design and the man behind the 5 cars on display. He spoke to us about the challenges in designing iconic cars like the Esprit as well as the goals for the design language for the Lotus range. Our favorite quite here was that the design for the new front ends has been inspired by the original Lotus Seven and if you look at the cars (especially the Elise) it does actually come through.

Finally we spoke to Wolf Zimmermann, CTO of Lotus about the challenges in rapidly developing 5 new cars. This was a great interview with reasons behind various decisions and we recommend you watch the whole video below. Significant points include:

- Aluminium bodies are required because composite cannot provide the required quality and shapes for the new designs

- Engines are not yet confirmed but will be decided in the next few months

- VVA architecture and manufacturing will have to be upgraded to meet targets

- Lotus Engineering is already involved in some of the design processes

Super 907

This article was written by GGLC member Jon Rosner and originally appeared in the June and July 2003 print editions of the Chapman report

It looked like a Lotus Seven, it was lipstick red with what looked like a round black nose that stretched back a couple of feet to touch the hood. Tall black leather seats with a wear spot high on the driver’s side and California tags “7LOTUS7”, the engine plate said Steel Bros, New Zealand.

It had a Lotus 907 engine in it and what looked like a Lotus Europa front suspension. One of the Books on Sevens had Steel Bros manufacturing maybe two dozen with the 907 Type Engine and many more with Ford-Lotus Twin Cam engines. It was for sale, but it was sold just hours before my offer of interest was left on an answering machine.

Fast forward to December 2001 and a tall thin fellow with piercing but tired eyes. His name is Dan Weatherly. He is driving a very original brown Europa with a rare dealer-type installed air conditioning system. And he had a very interesting story to tell.

“In 1975 I was looking around for an American sports car. I bought a new Corvette, it wasn’t even a real sports car in 1975. Then I started looking around and came across Steel Brothers in New Zealand. They were going to be celebrating their 100th Anniversary in 1977. They had started off by building wagons, then trucks – heavy manufacturing.”

“I started calling Dan Dixon, and back then transatlantic calling was no where near as common as it is today. And they took me seriously. Dixon had already brought the S4 Seven to New Zealand and were building the S4 since Caterham had gone back to making the S3.

The first time I went over there I got the chance to travel around New Zealand. And one day while I was walking around with David Dixon he told me to (with some sense of urgency, hands waving as story told) ‘hurry, come up to the top of the hill !’

So I rushed up and the he pointed out to me, in the middle of Auckland Bay, a single ship. He then proceeded to tell me, with a straight face, that this was the New Zealand Navy! He was teasing of course, but that was the attitude back then.”

“After two months of talking I wanted to buy a car from Steel Brothers and have it legal in the U.S. Dave Dixon was real car guy, and he was also the Project Manager for building the Series 4 Type 7 and a CPA.” “I told him that ‘I want to buy a car from you and legalize it in the US.’ This was an export hungry country!”

“At the time I was a twenty-seven year old investment salesman without a lot of money. Needless to say, I had to be more than I was, or this company would not have even begun to talk to me. Steel Brothers were excited by the idea of selling 200 cars per year in America.” Rod Steel was going to be a celebrity because he was going to do

something that hadn’t been done — he was going to build cars to sell to the US.”

“It was now June of 1977, my second trip to New Zealand.” I had a meeting with Rod, showed him the docs and two hours later we had a deal. Steel Brothers were builders of big tractor trailers, this was a sideline.”

“The first car I brought in (to the US) was a white Weber carbed S4 with a Ford-Lotus Twin Cam engine. The big problem was the evaporative system, so I went to fuel injection. Then Dave Dixon called and said that we can’t get the Twin Cams – This was AFTER I’d already paid the LA gray market importer with the mechanical whiz to do

the test engineering preliminaries leading to making it an EPA/DOT approved car. That was the bad news, the good news was that Lotus had the 907 engine legally in the US!!”

“Steel Brothers took the mold for the S4, cut it in half to widen it, and made the seats four inches wider. This car was not made to fit Colin Chapman, it was made to fit an American. They dropped in the 907 with the five speed and a higher rear axle, and shipped it to Olsen Engineering is Los Angeles.”

“They were a US Environmental Protection Agency approved firm. And I wanted to piggy-back on Lotus’ 50,000 mile Emissions Test. We had to test for four thousand miles in an approved test routine. It passed the Duration Test and the car was shipped directly to an E.P.A. Lab in Ann Arbor Michigan. “It couldn’t be driven. It couldn’t be moved. I didn’t see it for the first 3 months it was here.”

This was still 1977 timeframe, and there was a problem. The engine overheated every time the damn thing ran. E.P.A. does their testing inside, on a dyno. The gear-

shift knob had been stolen in transit. The result was that each time he ran the car through, the test engineer missed the shift, and the E.P.A. had the test stopped after five tries. I was real upset – so I asked them to ‘put a *&?#* shift knob on it’ and it passed on the sixth try (the air was filled with a thunder-cloud of his expressed exasperation.)”

“The next day I called the head of the E.P.A. and pleaded with the secretary, I told her the whole story, every (blessed) mistake, fifteen minutes (more steam.) I called the Project Manager (at E.P.A.) the very next morning and he told me that the car was done, it had passed everything – and then he laughed and asked me whom I knew in Washington. So the car came out clean !!!!”

“They gave me my 1978 EPA/CA certificate. That was REALLY an accomplishment I was proud of. It was legal, it was real, it could be sold in a dealership……and we did it on pennies!!”

“DOT did not require a crash test, but they did require it to meet bumper standards. The black nose on the car (rubberoid) met the five mile per hour test.” “Actually, we designed the 5 mph bumper but were never required to test it. The red 7 with the black nose had the only legal bumpers !!” “The engineers had said it would work, and we went with it.” “The DOT will let you say that this car is legal and that it meets all the standards… then you can start production.” “The kicker is that if you are found in violation of ANY of these (standards) then you can be fined $10,000.00 per violation, per car! We sent our documents in, done, we were legal.”

“Now we had our DOT/EPA street legal SUPER 907. I went to a contract attorney in Oakland and told him that I wanted a twenty year contract for exclusive rights. Then I placed a 3 by 5 ad in AUTO NEWS for the car and got 150 phone calls and 70 dealers sent me the required letterhead document stating that they would meet the minimum purchase of 5 cars.”

“I took the contract, the EPA and DOT docs, the sold order docs for more than the 75 cars they wanted to see orders for, flooring financing from Bank of America – which is financing for cars, and went back to New Zealand ready to do business.”

“Everything at the factory was as it was four months before when I was last there. None of the improvements I had been promised had been made.” “I had been paying the engineers OUT OF POCKET. There were no investors, it was all smoke and mirrors.” “But we signed the contracts and I stayed two weeks to see that they were making progress.” “I was a NOBODY, with NO money, but that I got THE job done.”

“My contract said that I had to buy a minimum of 200 cars each year to maintain my exclusivity. That’s an important number.” “In November, I called Lotus and said that I wanted 500 motors.” “I had been putting the pressure on Rod, so Rod had called Roger Putnam, Sales Manager for Lotus, and Mike Kimberly, Managing Director of Lotus over in England. They did not really want to sell him 200 907 motors because of the liability….. It was not worth it to them. But remember this was neither a yes nor a no.” Then Lotus called Rod Steel and gave him a definite no to 200 motors, the minimum purchase was 500 motors. And that was my play to goad Rod Steel into getting things moving again.”

“I was going real strong. I got Rod Steel to allow us to manufacture cars on my 3rd trip which was now August 1977.” But I was broke. I had left San Francisco with my American Express card and $5 cash. I could live on my AMEX card for one month.

I was in New Zealand for two months. I then got Rod to sign over the rights to build the S4 Seven and was preparing to leave.” “David Dixon and I formed a new company called ‘NEW ZEALAND AUTO MAKERS’ for the sole purpose of building the cars. “Dave had borrowed $60,000.00 of which I put $25,000.00 into my pocket. $20,000 was to pay the woman I had borrowed the $10,000 from.” “I had my car company. I had my contract with Lotus. I had all the pieces, but what I didn’t have was the money to make it come together.”

“We didn’t have any money. This would take three to four million to do. It would take a long time to get parts from England and Japan. There had to be a HUGE amount of float.” “Dave was a CPA and he knew a huge number of financial people. Dave started introducing new people at me. He had a friend in Auckland, and that firm wanted to put us together with another group.” “ This Aukland broker/dealer put us together with MOTORSPORTS INTERNATIONAL whose staff flew down to Christchurch for meetings and hot laps with a professional driver. The result was that we went into our meeting as high as marathon runners.

“We did the wine and dine route, we wanted MOTORSPECS INTERNATIONAL to take a 25% position. They were impressed with the car, and with the market for it – They were all smiles. They were a big company like a Target or a Walmart, but they were in the auto parts business like a Kragen. Dave Dixon and I were the two principals and we met everyone (at MOTORSPECS) from the Secretary to the CEO.” “One of the Board Members was a major stakeholder as his parents had started the company.”

“MOTORSPECS said they would take a 25% position for $350,000.00, not even close to what we needed. We needed three million to secure parts, car flooring and working capital. The Bank of New Zealand sat down with MOTORSPECS, David Dixon and myself and told us that they wanted collateral.”

“So I said, ‘look we need the bulk of the money for parts – hard assets.’ “These were the giants of New Zealand and I was the little guy.” “But I told them, ‘lend us $ three mil for parts which will be worth $ twelve mil in cars.’

“But what they did give us was the money to floor cars in America – with NO collateral from MOTORSPECS. The deal was done, the bar was opened, and everyone was drinking and telling jokes.”

“The proposal was done. I had my $3 million from the Bank of New Zealand and I had MOTORSPECS. One of the MOTORSPECS board members wanted to come to America, so I took him to Los Angeles and San Francisco.”

The MOTORSPECS Board Member was excited – he went back to New Zealand for the Board meeting, but he never made it to the meeting….. David Dixon too was out of the room, he had been sent to Australia – my main men were NOT at the meeting….”

“The decision came down – MOTORSPECS was NOT going to take a position – there was NO vote. This was a done deal and the ‘good ole boys’ had put in the word – the deal was dead.”

“I would have made this deal happen – BUT I made a big mistake. I alienated Rod Steel instead of befriending him, I had run out of money, I had run out of steam, I just didn’t which way to turn, and I was pretty upset.” “I started to fight Rod Steel, and I’m sorry I did.”

“The fourth trip was in March of 1979, after the ‘NO’ vote at MOTORSPECS everything that was good was no longer was there. I only had money for the airfare, the magic had vanished, and I went home.”

“Then three or four months later I got a phone call from Rod Steel’s attorneys. ‘He would like to import cars to the US but NOT through you.’ “ “’ What we would like to do is make a financial arrangement – and give you some money’ – PUSHY – take it or leave it.” “I said o.k. – you know my position. They offered me my expenses and some money.” “My attorney said to get them over here. He told me that there is no way they are going to import cars without us. They signed for $500 per car AND expenses if any cars ever came over —— no cars ever came over.”

“I had spent just short of $100,000, Dave Dixon was badly hurt financially – I was TOTALLY broke. My Super 907, the red one was repossessed because I could not make the payments on my $10g note to Bank of America.”

The one US legal Super 907 California plate 7LOTUS7, made a brief reappearance at British Car Day in Palo Alto, it was for sale and rumor had it that the engine was not in great shape. Then it disappeared again. After a fair bit of sleuthing Dan found what’s left being used as a plant potter in Oakland, California. That might have become a sad ending, but Dan’s not a quitter. In the process of getting another Super 907 from New Zealand Dan made the decision to go back into the production of a Super 7 type cars! Dan’s plans looks pretty cool and anyone who knows an angel investor who wants to do a really hot Lotus 7 type car can reach Dan Weatherly at his home in Walnut Creek, California!! Just tell him that you heard a story about the guy who had a dream and came THAT close to making it happen.

Update: This car has since been purchased by GGLC friend Kyle K who will be performing a full restoration on the car with his son. the following are current pictures of the car:

The Historic Grand Prix Experience

I recently had the pleasure of talking to long time GGLC member and Historic Grand Prix racer Chris Locke at the Monterey Motorsports Reunion. Chris has been campaigning his ex-Andretti JPS Lotus 77 in historic grand prix for five years and graciously agreed to share his experiences with the rest of the GGLC. The following is our exclusive interview with him discussing the Historic Grand Prix experience, the history of his car and comparing the 77 to other cars both new and old.

You can see more pictures of the Lotus 77 on the Flickr set below while video from the Monterey Motorsports Reunion Historic Grand prix is available here. For more info on Chris and his cars please visit Checkered Past Racing.